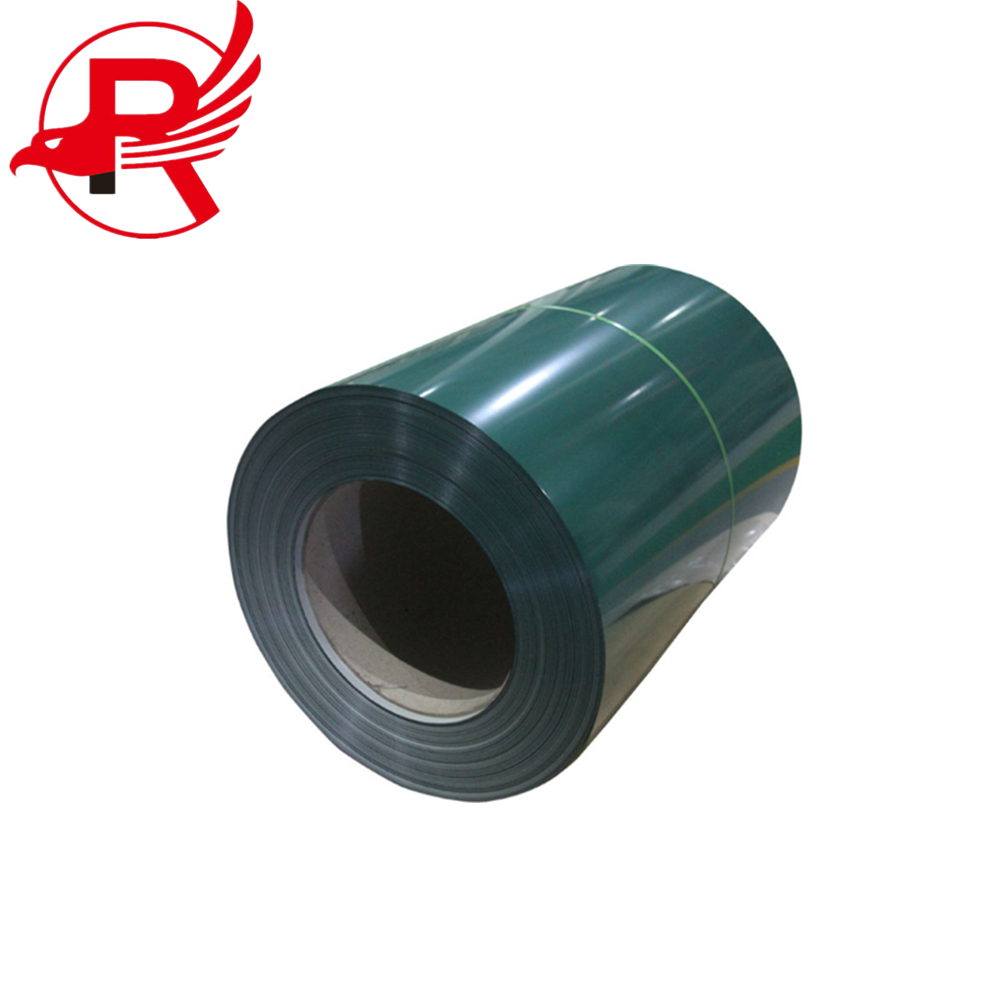

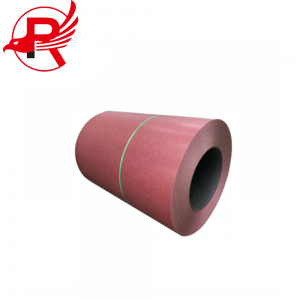

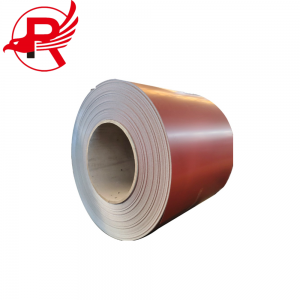

Hot Sale DX51D+z PPGI PPGL Kleurcoated Stiel Foarferve Kâldgewalste Stielspoel

| Produktnamme | Ral 9002/9006 ppgI foarskildere gi stielen coilppgi-spoelen |

| Materiaal | Q195 Q235 Q345 |

| SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

| Dikte | 0,125 mm oant 4,0 mm |

| Breedte | 600mm oant 1500mm |

| Sinkcoating | 40g/m2 oant 275g/m2 |

| Substraat | Kâld rôle substraat / waarm rôle substraat |

| Kleur | Ral Kleur Systerm of neffens keaper syn kleurmonster |

| Oerflakbehanneling | Chromatisearre en oalje, en anty-finger |

| Hurdens | Sêft, heal hurd en hurde kwaliteit |

| Gewicht fan 'e spoel | 3 ton oant 8 ton |

| Spoel-ID | 508mm of 610mm |

1)PPGIwurdt in soad brûkt yn grutte workshops, pakhuzen, kantoargebouwen, filla's, daklagen, loftreinigingskeamers, kâlde opslach, winkels.

2. KENINKLIKE GROEPPPGI, dy't mei de heechste kwaliteit en sterke leveringsmooglikheden in soad brûkt wurde yn stielstruktuer en konstruksje.

Noat:

1. Fergese sampling, 100% kwaliteitsfersekering nei ferkeap, stipe elke betelmetoade;

2. Alle oare spesifikaasjes fan PPGI binne beskikber neffens jo

eask (OEM & ODM)! Fabrykspriis dy't jo krije fan ROYAL GROUP.

It produksjeproses fan foarferve galvanisearre stielen coils omfettet ferskate wichtige stappen om de kwaliteit en prestaasjes fan it einprodukt te garandearjen. Hjir is in oersjoch fan it typyske produksjeproses:

MateriaalseleksjeIt proses begjint mei de seleksje fan galvanisearre stielen coils fan hege kwaliteit. Dizze coils binne typysk makke fan kâldwalst stiel dat bedekt is mei in laach sink om korrosjebestriding te bieden.

OerflakreinigingDe galvanisearre stielen rollen wurde ûnderwurpen oan in yngeande reinigingsproses om oalje, smoargens of oare fersmoarging fan it oerflak te ferwiderjen. Dit is essensjeel om in goede hechting fan 'e fervelaag te garandearjen.

OerflakbehannelingNei it skjinmeitsjen kinne de stielen coils oerflakbehannelingsprosessen ûndergean lykas gemyske konverzjecoating of chromaatpassivaasje om de hechting fan 'e ferve fierder te ferbetterjen en de korrosjebestriding te ferbetterjen.

Primer-tapassingIn primerlaach wurdt oanbrocht op it skjinmakke en behannele stielen oerflak. De primer helpt de hechting fan 'e topcoat te befoarderjen en biedt ekstra korrosjebeskerming.

Topcoat-tapassingDe foarferve galvanisearre stielen rollen wurde dan bedekt mei in toplaag fan spesjaal formulearre ferve. Dizze ferve is ûntworpen om kleur, duorsumens en ekstra beskerming te jaan tsjin miljeufaktoaren lykas UV-strieling en focht.

ÚthardingDe beklaaide stielen rollen wurde troch in úthardingsoven laat dêr't de ferve op it oerflak bakt wurdt. Dit proses soarget foar goede hechting en ferbining fan 'e ferve, wat resulteart yn in duorsume en langduorjende finish.

Koeling en ynspeksjeNei it útharden wurde de foarferve galvanisearre stielen rollen ôfkuolle en ynspektearre foar kwaliteitskontrôle. Alle defekten of ûnfolsleinheden wurde identifisearre en oanpakt foardat de rollen klearmakke wurde foar ferstjoering.

Snijden en ferpakkenDe ôfmakke coils kinne ûndergean oan it snijen om de winske breedte te berikken en wurde dan ynpakt en taret foar distribúsje oan klanten.

Ferpakking is oer it algemien troch stiel izeren pakket en wetterticht pakket, stielen strip bining, tige sterk.

As jo spesjale easken hawwe, kinne jo roestfêste ferpakking brûke, en moaier.

Transport:Ekspres (Sample Delivery), Loft, Spoar, Lân, Seeferfier (FCL of LCL of Bulk)

F: Binne jo in fabrikant?

A: Ja, wy binne in fabrikant. Wy hawwe ús eigen fabryk yn Tianjin City, Sina.

F: Kin ik in proefbestelling hawwe foar mar in pear tonnen?

A: Fansels. Wy kinne de fracht foar jo ferstjoere mei LCL-tsjinst. (Minder kontenerlading)

F: As sample fergees is?

A: Foarbyld fergees, mar de keaper betellet foar de fracht.

F: Binne jo goudleveransier en dogge jo hannelsfersekering?

A: Wy binne sân jier goudleveransier en akseptearje hannelsfersekering.